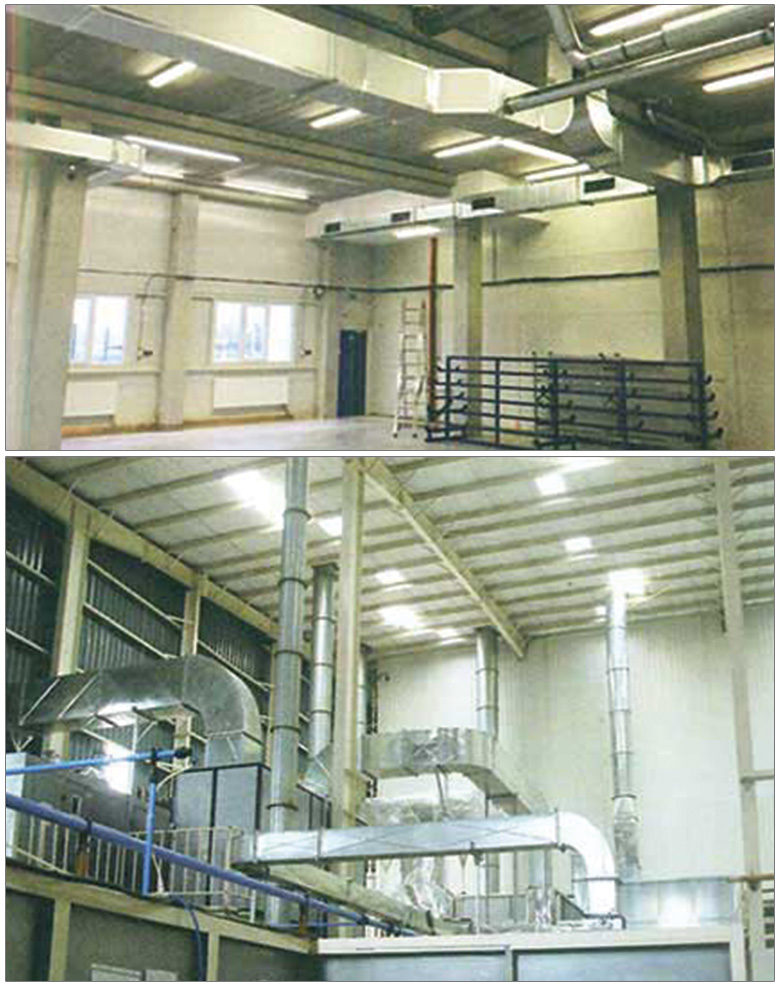

Ventilation Systems

Ventilation is the international introduction of outdoor air into a space and is mainly used to control indoor air quality by diluting and displacing indoor pollutants; it can also be used for purposes of thermal comfort or dehumidification.

The international introduction of outdoor air can be categorized as either mechanical ventilation or natural ventilation.[2] Mechanical Ventilation uses fans to drive the flow of outdoor air into a building. This may be accomplished by pressurization (in the case of positively pressurized buildings) or by depressurization (in the case of exhaust ventilation systems) passive flow of outdoor air into a building through planned openings (such as louvers, doors and windows). Natural Ventilation does not require mechanical systems to move outdoor air, it relies entirely on passive physical phenomena, such as diffusion, wind pressure or the stack effect. Mixed mode ventilation systems use both mechanical and natural process. The mechanical and natural components may be used in conjunction with each other or separately at different times of day or season of the year.[3] Since the natural component can be affected by unpredictable environmental conditions it may not always provide an appropriate amount of ventilation. In this case, mechanical systems may be used to supplement or to regulate the naturally driven flow.

In many instances, ventilation for indoor air quality is simultaneously beneficial for the control of thermal comfort. At these times, it can be useful to increase the rate of ventilation beyond the minimum required for indoor air quality. Two examples include air side economizer strategies and ventilative pre-cooling. In other instances, ventilation for indoor air quality contributes to the need for and energy use by mechanical heating and cooling equipment. In hot and humid climates, dehumidification of ventilation air can be a particularly energy intensive process.

Ventilation should be considered for its relationship to “venting” for appliances and combustion equipment such as Water Heaters, Furnaces, Boilers and Wooden Stoves. Most importantly the design of building ventilation must be careful to avoid the back draft of combustion products from “naturally vented” appliances into the occupied space. This issue is of greater importance in new buildings with more air tight envelops. To avoid the hazards, many modern combustion appliances utilize “direct venting” which draws combustion air directly from outdoors, instead of from the indoor environment.

The main equipment to be properly designed are Fan, Duct Line, temperature of inside and outside air and dehumidification. The application is in big Industrial Houses, Material storage Area, Thermal & Hydro electric power plant, Tunnels, Car parking areas basement of Hospitals etc.

WhatsApp For Best Price

Contact Us